Menu

Menu

- INTELLIGENT WIRE POLISHING MACHINE

- Home

- About

- Product

- DIAMOND SPIRAL BANDS

- 3M Flexible Diamond Grinding Wheel 6440J Black D30

- 3M Flexible Diamond Grinding Wheel 6440J Black D30

- 3M Flexible Diamond Grinding Wheel 6440J Green D30

- 3M Flexible Diamond Grinding Wheel 6440J Green D30

- 3M Flexible Diamond Grinding Wheel 6440J Yellow D30

- 3M Flexible Diamond Grinding Wheel 6440J Yellow D30

- 3M Even Run Schuurband 6440J YELLOW 18N40 30X30MM

- Diamond spiral band abrasives

- Diamond spiral sanding bands

- Diamond spiral bands & drums

- Diamond debris ball spiral bands

- Diamond Spiral Band Drums

- Diamond No-Lap Spiral Bands

- DIAMOND FLAP WHEEL

- DIAMOND FLAP DISC

- Grinding Wheel for Knife and Fork

- Diamond flap disc bunnings

- Electroplated diamond flap disc

- 100mm diamond flap disc

- Hybrid diamond flap discs

- Diamond wheel flap disc

- 115mm diamond flap disc

- Concrete sanding disc

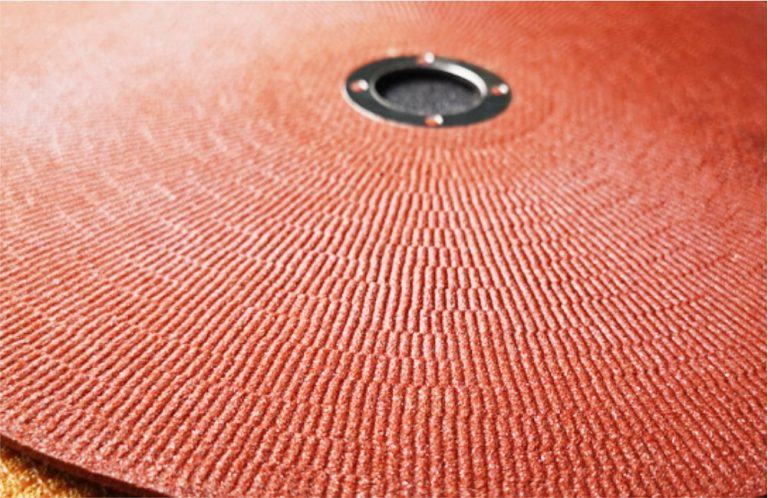

- Fiexible Grinding Wheel

- Elastic Fast Aggressive Grinding Wheel

- Grinding Disc

- Wa Material Disc for Aluminum Copper

- DIAMOND SANDING BELTS

- DIAMOND SANDING PADS

- DIAMOND HAND PADS

- DIAMOND SPIRAL BANDS

- Application

- Contact

- Blog