Applications of Diamond Sanding Abrasive Belts and CBN Sanding Belts (Including Lanboon’s Relevant Context)

Diamond and CBN (Cubic Boron Nitride) sanding abrasive belts can be widely used for grinding a variety of hard and brittle materials. These include steel, stone, glass, ceramics, monocrystalline silicon, polysilicon, zirconia, alumina, metal-nonmetallic synthetic materials, cemented carbide, aluminum-magnesium alloy, aluminum-beryllium alloy, titanium alloy, and more. Lanboon, as a provider in this field, offers high-quality abrasive belts that cater to these diverse applications.

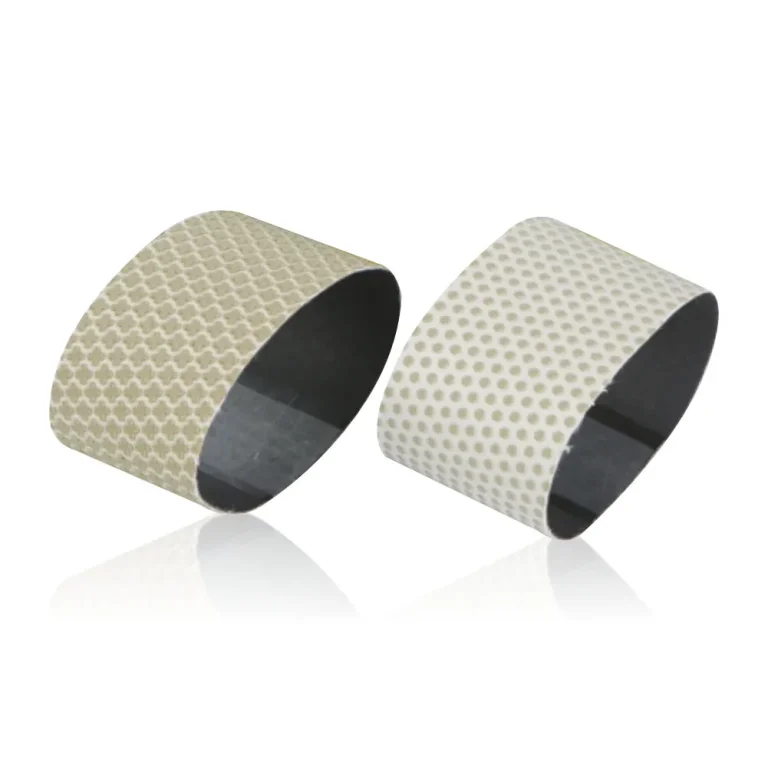

Diamond Sanding Abrasive Belts

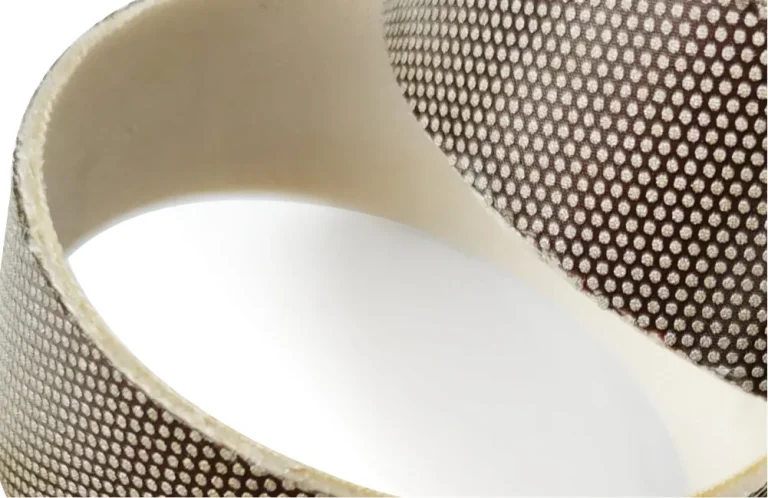

The size of a diamond emery strip is typically longer than that of a conventional sanding belt, with both sides requiring extra uncoated dimensions for import and export purposes. Electroplated diamond emery strips, such as those offered by Lanboon, are specifically designed to tackle difficult-to-grind materials like stones, glass, ceramics, metals, carbides, and composites. The sharp-cut diamond minerals, combined with a flexible backing, make these abrasive belts an excellent match for a variety of metal processing applications.

Key Features and Benefits

- Consistent Edge Quality: Lanboon’s diamond sanding abrasive belts ensure uniform grinding results, maintaining consistent edge quality throughout the process.

- Compatibility with Portable Sanders: These belts fit portable sanders that use 1-1/8″ x 21″ (29 x 533 mm) belts, providing versatility and convenience in various workshop settings.

- Longer Life Than Silicon Carbide Belts: The durability of diamond abrasive belts surpasses that of traditional silicon carbide belts, reducing the frequency of belt replacements and enhancing overall productivity.

- Wide Range of Sizes and Grits:

- Popular sizes: 50, 75, 100, 150, 200, etc.

- Other sizes: Can be custom-made to meet specific requirements.

- Popular grits: 60#, 120#, 200#, 400#

- Available grits: 30#, 60#, 120#, 200#, 400#, 600#, 1000#, 2000#, 3000#

Example Parameters of Diamond Sanding Belts for HVOF WC Coating

Diamond sanding abrasive belts are a type of coated abrasive tool that utilizes superhard material (synthetic diamond) abrasive particles adhered to a flexible base by a bond. These belts can be divided into metal nickel plating electroplated bond and resin bond types, with the resin bond further consisting of flexible and hard variants. In some applications, the grinding performed by diamond sanding belts in the thermal spray coating industry can replace that of diamond grinding wheels and film polishing. Diamond sanding belts are capable of completing both the grinding and polishing processes efficiently. Recently, they have been widely adopted in the thermal spray coating industry, as well as in the production and repair of hydraulic cylinders and turbine blades. Lanboon’s diamond sanding belts, with their superior performance and reliability, are well-suited for these demanding applications.

In summary, Lanboon’s diamond sanding abrasive belts offer a versatile and durable solution for grinding a wide range of hard and brittle materials. Their consistent edge quality, compatibility with portable sanders, longer life, and wide range of sizes and grits make them an ideal choice for various metal processing and thermal spray coating applications.